Managing Constraints and Pacemakers

Managing Constraints and Pacemakers

Why use it?

Managing constraints and pacemakers reduces lead time, inventory, waiting, and unevenness. It increases capacity and responsiveness to customer demands.

What does it do?

Managing constraints and pacemakers is a method to identify and systematically improve constraints and to manage pacemaker processes.

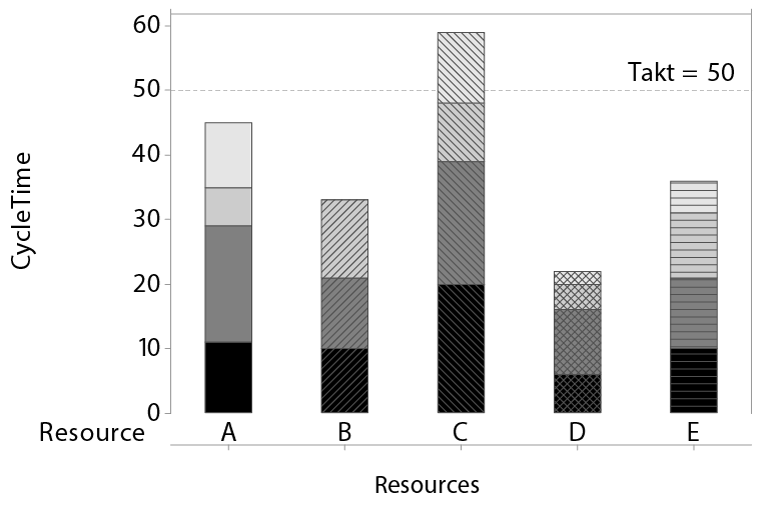

The constraint is the bottleneck process in the value steam that limits the actual capacity. The constraint has to be systematically improved until it is no longer the limiting factor. Constraints exist whenever workloads are unbalanced. In the operator balance chart below, resource C is the constraint.

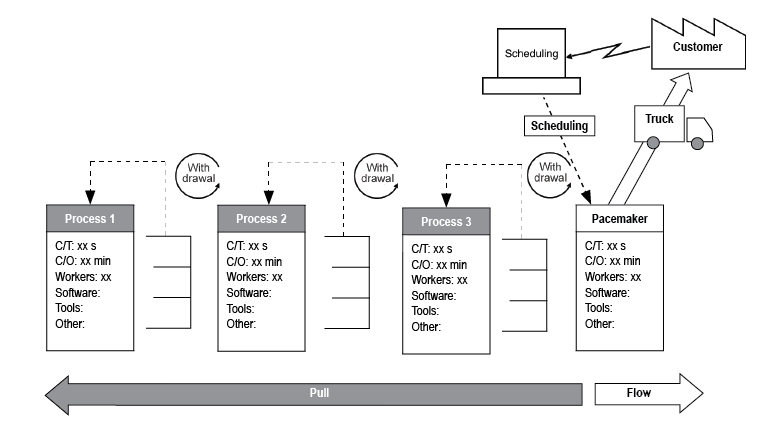

The pacemaker process is the single scheduling point in your value stream that connects to the customer. Upstream of the pacemaker, production is determined by the kanban pull system. Flow must exist within the pacemaker process itself. The pacemaker process is typically the most downstream continuous-flow process in the value stream.

How do I do it?

- Identify the constraint. The constraint is usually the process step with the most work-in-process (WIP) inventory waiting to be worked on. It can also be identified by the highest bar in an operator balance chart

- Limit the pace of other non-bottleneck process steps to the pace of the constraint

- Balance the workload to create evenness and reduce the cycle time of the constraint

- Identify the next constraint and systematically improve it as well. Continue until all constraints that prevent you from reaching your goals are removed

- Set up a pull system with kanbans between process boxes (note that a process box in a VSM should represent an area where there is continuous flow)

- Designate the most downstream continuous-flow process as the pacemaker process and send the production schedule to it. The pacemaker process then sets the pace for the rest of the processes in the value stream