Let Customers Pull

Kanban System

What is it?

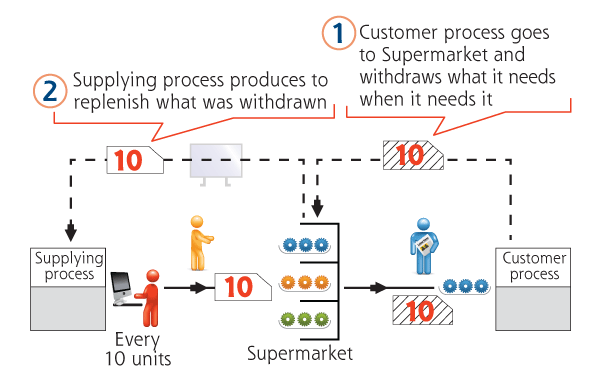

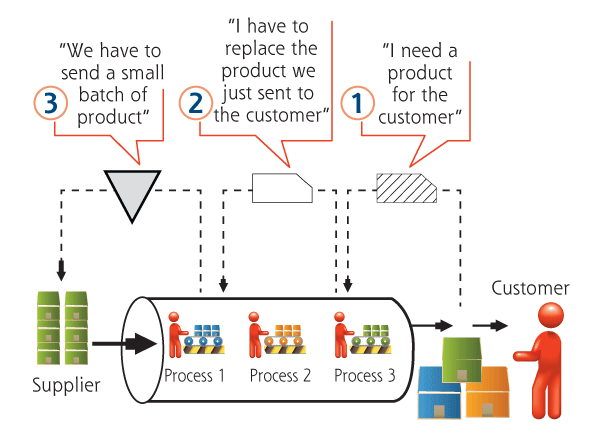

A method of using visual signals (kanban) for triggering or controlling the flow of materials between processes internally or with outside suppliers.

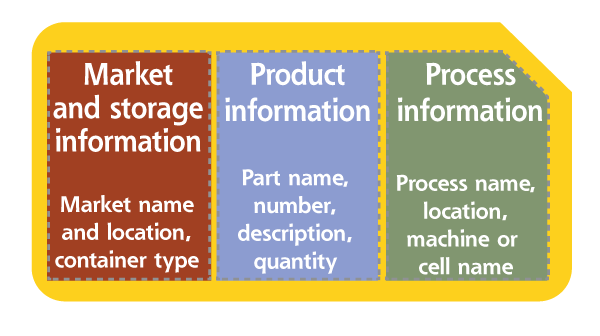

Typical Kanban card

Why use it?

- Prevents overproduction as demand varies

- Provides specific production instructions of timing and quantity

- Serves as a quick visual control tool for production (Are you ahead or behind schedule?)

- Establishes a tool for continuous improvement (reduction of the number of kanban)

The Kanban “Talk”

The Six Kanban Rules

Follow these six kanban rules:

- Downstream processes always come to withdraw

- Produce only the quantity withdrawn

- Don’t send defects to the next process

- Kanban should be attached to the actual parts containers

- For kanban to work, production must be leveled

- The best kanban is not needing a kanban

How do I do it?

- Validate three conditions:

- Flow cannot be achieved between the two processes at this time. Remember rule number 6.

- Equipment, process and people are reliable most of the time, at least 80% of the time.

- Production has been leveled to avoid overcapacity and out of stock items

- Calculate the number of kanban cards (N):

N = [(Average Demand x Lead Time) + Buffer Stock + Safety Stock] / Container Size

Buffer = Inventory due to sudden fluctuations in customer orders

Safety Stock = Inventory due to reliability issues in the process

- Define the kanban cards and process for production and withdrawal. Train all participants by simulating the actual process

- Implement and follow until kanban system is stable

Kanban systems are used only after a line has been stabled and balanced.

Next:

7. Pursue Perfection